DIMO has always been in the forefront of introducing innovative and affordable agri machinery to the local farming community with the aim of driving mechanization in the agriculture sector of the nation.

The current machinery available for rice transplanting, in the Sri Lankan agriculture sector, possesses the capability of maintaining 11 to 12 inches between rice seedling rows when being planted.

In comparison, the Pela Batta can reduce it to an 8-inch gap.

It also ensures a 5-to-6-inch gap (variable as per requirement) between each individual seedling in a given row.

Research has shown that this new machine will lead to an increase in agricultural yield by 20%-30% as a result of the more consistent spacing being maintained between seedlings.

Additionally, the number of seedlings planted can also be increased.

The traditional process of planting rice seedlings is significantly labour intensive and certain methods do not maintain a level of consistency.

The Pela Batta addresses both these concerns and delivers economic benefits, as a result.

It can plant an area covering 3 to 3.5 acres per day, effectively increasing the efficiency of the planting process in rice cultivation.

Furthermore, the consistent space maintained between the rice plants will make the process of weed and pest control relatively convenient.

It must be particularly noted that this machine successfully planted 100 acres of land during this year's Yala season.

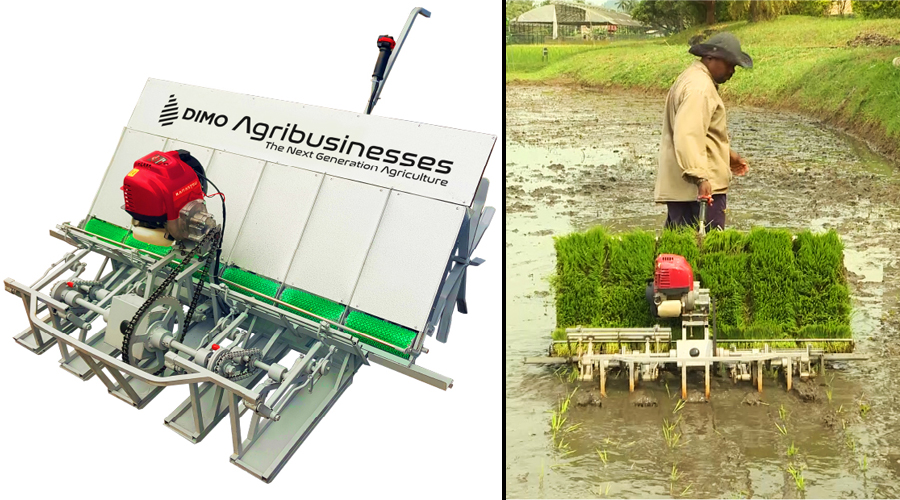

The 4-stroke engine, the simple design and the reduced weight of the Pela Batta machine makes it easily operable by anyone.

The overall robustness, ease of maintenance and the low maintenance costs make it highly beneficial for the user.

Rohana Thilakasiri, Principal Agriculturist (Paddy) of Rice Research and Development Institute at Bathalagoda stated,

“The existing paddy transplanting machinery are mainly used in countries such as China, Korea and Japan, where the paddy varieties are long term and tall, allowing the distance between seedling rows to be up to 12 inches.

However, Sri Lanka uses short term varieties of paddy which are short in height and usually harvested within 3-3.5 months.

As a result, it is not viable for Sri Lankan farmers to use such machinery simply because they suit other nations.

When paddy transplanting is carried out with a 12-inch distance between the rows, this large gap creates difficulties in managing the growth of weeds in between.

We believe that the 8-inch gap is ideal for our farming communities and will provide much better yields, especially considering the rice varieties we currently cultivate.”

Expressing his views, Rajeev Pandithage - Director of DIMO who also oversees the Agri Machinery business of the Group, said:

“Fuelling the dreams and aspirations of the farming community of the country, DIMO constantly promotes agriculture mechanization.

The newly introduced Pela Batta will help realise that objective, and coupled with over 8 decades of DIMO trust and engineering excellence, unwavering DIMO warranty, and the invaluable after-sale service through an island wide branch network, we firmly believe that this machine will be in high demand among the Sri Lankan farming community.”

Through DIMO Agribusinesses, DIMO continues to provide substantial support towards the wellbeing and development of the next generation of agriculture in Sri Lanka.

Image Caption Pela Batta paddy transplanting machine from DIMO.